| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : VIIPLUS Sleeve & Bearing

Model Number : Metric Cylindrical Metal-Polymer Low Friction Plain Bearings Bush alternative

Certification : ISO 3547 DIN 1494 Assembly Standard Tolerance

Place of Origin : Composite plain cylindrical bushings manufacturer

MOQ : 50 Piece/Pieces

Price : Negotiable

Payment Terms : T/T, L/C, Western Union,

Supply Ability : Special Customized Lubricating Bushings Manufacturing

Delivery Time : 2~4 Weeks

Packaging Details : Export carton; Wooden case ; Wood pallet.

Size : Metric Sizes,Available from stock

Meterial : Support material Steel Sintered bronze Sliding layer

Application : hydraulic oil lubrication

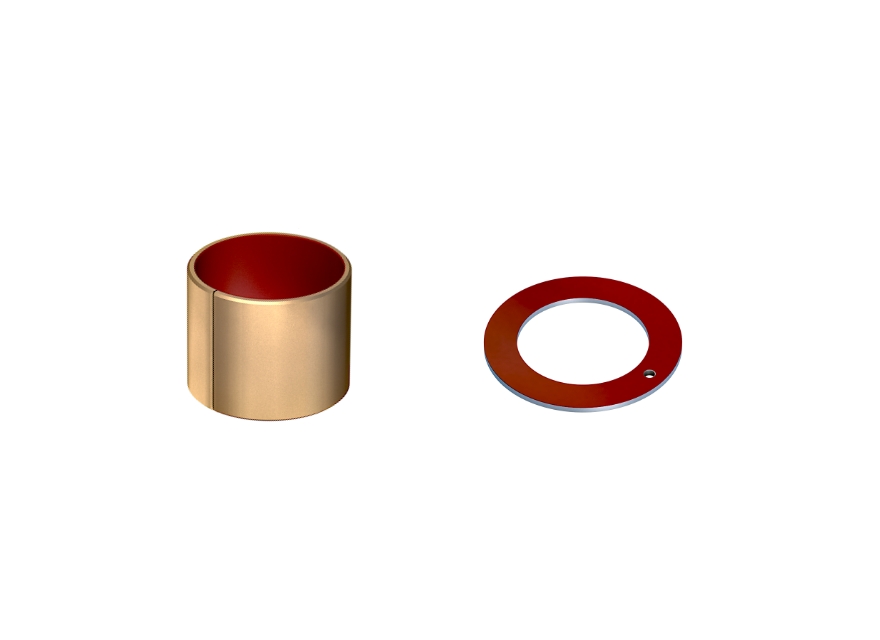

Type : Wrapped Bushes, Flanged Bearing, Thrust Washer

Plating : tin-plated or copper-plated

Bearing Bushing Factory Price : tiffany@viiplus.com

Self-lubricating Bearing Bushing Manufacturer : https://www.viiplus.com/

High Light : Self Lubricating Bronze POM Bushing, Metal polymer bushings

POM DX BUSH : marginally lubricated bushings for grease or oil lubricated applications · Standard split bushings contain grease indents in the sliding layer; plain sliding ...

Bush Bearings Manufacturers Suppliers Exporters : plain bearings. Long, maintenance-free service, manufactures bushings in various designs and from different materials. tiffany@viiplus.com, Bushings - Configure and purchase - https://www.viiplus.com/

Steel-backed polymer plain bearings with a flange type design are specifically suitable for hydraulic oil lubrication. These bearings offer excellent wear resistance and corrosion resistance, ensuring reliable performance in various hydraulic systems. The steel backing provides added strength and stability, while the material ensures smooth operation and efficient lubrication. The flange type design allows for easy installation and integration into hydraulic machinery. Overall, these bearings are an ideal choice for hydraulic oil lubrication applications, delivering high performance and durability.

DIN 1494 / ISO 3547 Also available: lead free!Special dimensions are only available on request.It is a dry sliding bearing with a sliding layer. Lubrication is therefore not necessary. But it is suitable for lubricated applications (such as hydraulic oil lubrication).

VIIPLUS offers an extensive range of sliding bearings to fulfil your needs!With our China engineering know-how and our extensive range of bushing materials, we are able to solve nearly every Dry Sliding Bearing issue.

Plain bearings. Appearance and characterization of damage to metallic hydrodynamic bearings.

| Product Name | Steel Bushing |

| Max Load Capacity | Static load 250N/mm2 ; Dynamic load 140N/mm2 |

| Max Load Speed | Dry friction 2.5m/s ; Oil lubrication 5.0m/s |

| Max PV Value Limit | Dry friction 3.6N/mm2 m/s ; Oil lubrication 50N/mm2 m/s |

| Friction Coefficient | Dry friction 0.08~0.20 ; Oil lubrication 0.02~0.07 |

| Work Temperature | -195℃~+280℃ |

| Thermal Conductivity | 42w/m k |

| Production Process | Material cutting~Bronze sintering~ sintering~Sizing~Coiling~Surface finish~Packing |

| Application Feature | Self lubrication, Low wear, Low friction, Low noise, Good sliding characteristic, Pb free |

Housing ØH7 Bushing inner-Ø after mounting H9 Shaft tolerancef7 to h8

Self-lubricating bearings type

du bushing size chart

| Di (mm) | Do (mm) | Sfl (mm) | Dfl (mm) | B (mm) | bearing | shaft | The largest diameter (mm) | Minimum diameter (mm) | The maximum clearance(mm) | The minimum clearance(mm) | |

| BB0304DU | 3 | 4.5 | 0.75 | 7 | 4 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| BB0404DU | 4 | 5.5 | 0.75 | 9 | 4 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| BB0505DU | 5 | 7 | 0.925 | 10 | 5 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| BB0604DU | 6 | 8 | 0.925 | 12 | 4 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| BB0608DU | 6 | 8 | 0.925 | 12 | 8 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| BB0806DU | 8 | 10 | 0.925 | 15 | 5.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB0808DU | 8 | 10 | 0.925 | 15 | 7.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB0810DU | 8 | 10 | 0.925 | 15 | 9.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB1007DU | 10 | 12 | 0.925 | 18 | 7 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1009DU | 10 | 12 | 0.925 | 18 | 9 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1012DU | 10 | 12 | 0.925 | 18 | 12 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1017DU | 10 | 12 | 0.925 | 18 | 17 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1207DU | 12 | 14 | 0.925 | 20 | 7 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1209DU | 12 | 14 | 0.925 | 20 | 9 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1212DU | 12 | 14 | 0.925 | 20 | 12 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1217DU | 12 | 14 | 0.925 | 20 | 17 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1412DU | 14 | 16 | 0.925 | 22 | 12 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| BB1417DU | 14 | 16 | 0.925 | 22 | 17 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| BB1509DU | 15 | 17 | 0.925 | 23 | 9 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1512DU | 15 | 17 | 0.925 | 23 | 12 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1517DU | 15 | 17 | 0.925 | 23 | 17 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1612DU | 16 | 18 | 0.925 | 24 | 12 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| BB1617DU | 16 | 18 | 0.925 | 24 | 17 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| BB1812DU | 18 | 20 | 0.925 | 26 | 12 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB1817DU | 18 | 20 | 0.925 | 26 | 17 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB1822DU | 18 | 20 | 0.925 | 26 | 22 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB2012DU | 20 | 23 | 1.45 | 30 | 11.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2017DU | 20 | 23 | 1.45 | 30 | 16.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2022DU | 20 | 23 | 1.45 | 30 | 21.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2512DU | 25 | 28 | 1.45 | 35 | 11.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB2517DU | 25 | 28 | 1.45 | 35 | 16.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB2522DU | 25 | 28 | 1.45 | 35 | 21.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB3016DU | 30 | 34 | 1.95 | 42 | 16 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| BB3026DU | 30 | 34 | 1.95 | 42 | 26 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| BB3516DU | 35 | 39 | 1.95 | 47 | 16 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| BB3526DU | 35 | 39 | 1.95 | 47 | 26 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| BB4016DU | 40 | 44 | 1.95 | 53 | 16 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| BB4026DU | 40 | 44 | 1.95 | 53 | 26 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| BB4516DU | 45 | 50 | 2.45 | 58 | 16 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| BB4526DU | 45 | 50 | 2.45 | 58 | 26 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

Machine and plant construction, textile processing and agricultural maschines, hydraulic pumps, automotive industry

sliding bearing and bushing technology

1. No oil lubrication or less oil lubrication, suitable for places where it is impossible to add oil or it is difficult to add oil. It can be used without maintenance or with less maintenance.

2. Good wear resistance, small friction coefficient and long service life.

3. There is an appropriate amount of elastoplasticity, which can distribute the stress on a wider contact surface and improve the bearing capacity of the bearing.

4. The static and dynamic friction coefficients are similar, which can eliminate crawling at low speed, thereby ensuring the working accuracy of the machine.

5. It can make the machine reduce vibration, reduce noise, prevent pollution and improve working conditions.

6. The transfer film can be formed during the movement to protect the friction shaft without biting the shaft.

7. The hardness of the friction shaft is low, and more shafts without tempering treatment can be used, thereby reducing the difficulty of processing related parts.

8. Thin wall structure, light weight, can reduce mechanical volume.

9. A variety of metals can be electroplated on the back of the steel, which can be used in corrosive media; it has been widely used in sliding parts of various machines.

simple solutions – flawless products – high quality services – performance-based prices.

FOLLOW US ON

|

|

Steel Backed Polymer Plain Bearings Flange Type For Hydraulic Oil Lubrication Images |