| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : VIIPLUS BUSHINGS SUPPLIER

Model Number : BUSHINGS

Certification : ISO 3547 DIN 1494 Assembly Standard Tolerance

Place of Origin : Composite plain cylindrical bushings manufacturer

MOQ : 1000 Piece/Pieces

Price : $0.05 - $1.00 / Pieces

Payment Terms : TT in advance,Western Union

Supply Ability : Special Customized Lubricating Bushings Manufacturing

Delivery Time : 7~15 work days

Packaging Details : Packaging: Export carton; Wooden case ; Wood pallet.

Meterial : Carton steel , Bronze , STRIPS

Plating : Tin or copper

Type : Sheet

Customized : Available as per drawing

Special Use : High-strength Steel Plate

Features : Wear,Dry,Low Resistance

Port : ShangHai

Application : hydraulic special Sliding

Bearing Bushing Factory Price : tiffany@viiplus.com

Self-lubricating Bearing Bushing Manufacturer : https://www.viiplus.com/

High Light : Self Lubricating Bronze POM Bushing, Metal polymer bushings

POM BUSH : marginally lubricated bushings for grease or oil lubricated applications · Standard split bushings contain grease indents in the sliding layer; plain sliding ...

Bush Bearings Manufacturers Suppliers Exporters : plain bearings. Long, maintenance-free service, manufactures bushings in various designs and from different materials. tiffany@viiplus.com, Bushings - Configure and purchase - https://www.viiplus.com/

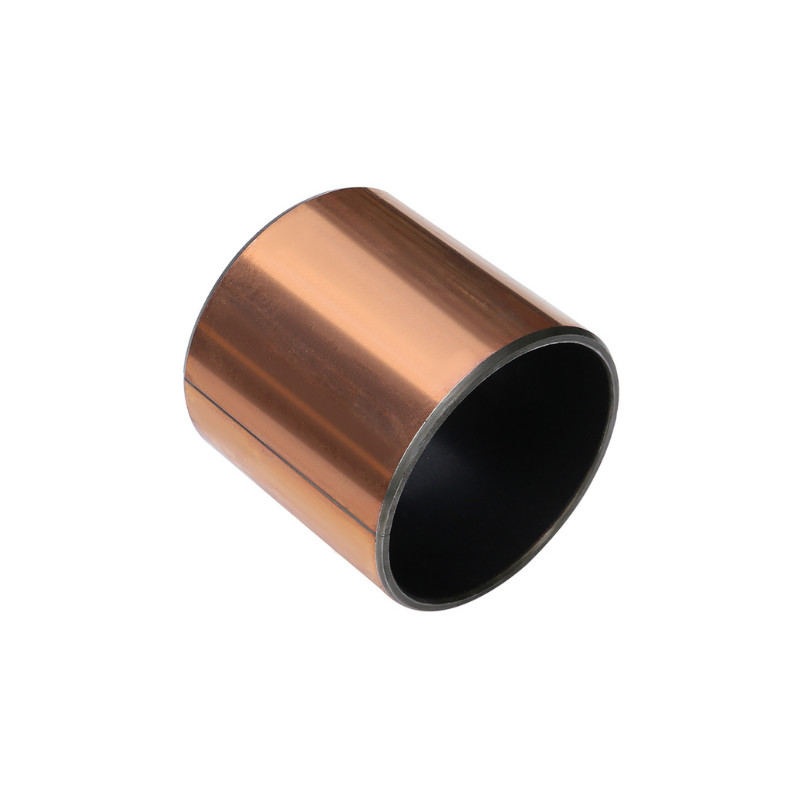

Precision Assembly Dimension & Size Composite Metal Bearings for Fluid Power Systems Pump Bushes are designed to meet the exacting requirements of fluid power systems. These bearings, constructed with a composite of and metal, offer superior wear resistance and corrosion resistance, ensuring long-term reliability and durability. The precision assembly dimensions and sizes of these bearings guarantee a precise fit and optimal performance in pump bushes. The composite material combines the strength and rigidity of metal with the lubrication and low-friction properties of , resulting in efficient and smooth operation of fluid power systems. Overall, these precision-engineered bearings are an ideal choice for fluid power systems pump bushes, delivering reliable and efficient performance in various industrial applications.

Metal composite bearings have been relatively successful in replacing traditional lead-bearing bronze or bimetallic bearings in many lubrication applications.But until recently, funds are still unable to match the metal genera - polymer sliding bearing alloy bearing assembly dimension precision, which limits its application in specific areas, in these areas, the axial clearance control to the improvement of operation efficiency, or noise, vibration and no comfort plays an extremely important role.

VIIPLUS Bearings supply a variety of pump metal bushings including brass bushings, steel bushing, & bronze bushings. If you already know which type of metal bushing is right for your application, you can quickly navigate to it below for more information:

Self-lubricated bearings have been used in vane pumps and the results show that the metal polymer composite straight liner has excellent tribological performance under dry, edge and hydrodynamic lubrication operating conditions, providing excellent pump reliability.

In order to improve the reliability of the pump, VIIPLIUS provides a self-lubricating bearing solution.

Provides a wide variety of self-lubricating sliding bearings to meet or even exceed the needs of a variety of applications.It is used in rotating, swinging and sliding motions and in a variety of difficult operating conditions such as high static or vibrating loads, temperature limits and friction conditions.

VIIPLUS SLIDING BEARING series self-lubricating bearings can meet the unique application requirements of the fluid power industry.We can provide complete solutions, reliable performance under high load and high speed, can resist cavitation and chemical corrosion, suitable for today's advanced fluid power applications, in gear pump, piston pump, vane pump, compressor, cylinder and other industries have a wide range of application.

The benefits of self-lubricating straight bearings are as follows:

Self-lubricating bushing with -based low friction bearing cladding for extended service life to avoid lining and shaft damage while operating under dry or boundary lubrication conditions

Thin - walled, single - piece structure allows for compact, lightweight pump design

Easy to assemble in pump without expensive tools and equipment

Environmentally friendly lead-free bearing assembly.

This requires self-lubricated bearings to provide high wear resistance, fatigue and flow erosion hydrodynamic composite bearing bearing bush solutions

The technical requirements and specific functions of sliding bearings in this application are the most demanding requirements of any high-power hydraulic components.In addition to withstand the temperature range in - 50 ℃ to + 140 ℃ as well as the wide range of lubricant viscosity change, must be able to withstand extreme high load bearing oscillation velocity and boundary lubrication conditions.

Maintenance-free bearings are used in common hydraulic fluid and many types of water emulsion conditions, suitable for vane pumps, gears, plunger pumps and motors.In addition to their excellent frictional and anti-wear properties, they are stable and reliable under required loads and speeds, making them suitable for many hydrodynamic applications.

Application requirements

Variable displacement axial piston pumps are used in many industries of high power hydraulic systems, including aerospace, automotive, construction equipment, agricultural equipment, machine tools, etc.These pumps provide variable flow from zero to maximum capacity for the system actuators.The change of flow is realized by the change of the position of the swash plate.

We provide bearing solutions for hydraulic pumps and motors, including shaft bearings, half bearings, thrust blocks, wear plates, hydraulic cylinders, connecting rod bearings.Even with the most stringent application requirements, our customers can still rely on our high strength, scratch resistance and low friction aluminum alloy bearings.

· external gear pump and motor

· vane pump and centrifugal pump

· radial and axial plunger pumps

· internal gear pump and radial piston motor

The rotary vane pump provides hydraulic power for the automatic transmission.

Located on the transmission cover, they pull oil at low pressure from the sump at the bottom of the transmission and feed it at high pressure to the hydraulic system, the gearbox cooler, and the torque converter.

The blade rotor is supported by bearings on the front and rear plates.

When mounted on the backplane, needle roller bearings may fail due to lack of oil, especially after a long rest in different climatic conditions or during repeated start and stop operation.

1.Improve energy efficiency

2.Maintenance free,

3. Reduce noise and assembly costs

4.Replace expensive rolling bearings

Max. load | Static | 250N/mm2 |

Dynamic | 140N/mm2 | |

Max. speed | Dry | 2m/s |

Lubrication | >2m/s | |

Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

Continuous | 1.8N/mm2*·m/s | |

PV | Hydrodynamic | 30N/mm2*·m/s |

Temp. | -195℃~+280℃ | |

Friction coefficient | 0.03~0.20 | |

Thermal conductivity | 42W (m·k)-1 | |

Coefficient of thermal expansion | 11*10-6k-1 | |

· Metal-Polymer Composite Bushing Material

· Steel back + Porous Bronze Sinter +

· + Fillers

OPERATING PERFORMANCE | |

Dry | Good |

Oil lubricated | Very Good |

Grease lubricated | Good |

Water lubricated | Fair |

Process fluid lubricated | Good |

* Depending on operating conditions

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

· Thrust washers

· Flanged washers

Metric bearings and imperial bushings made to order: Standard bushing forms in special sizes, half-bushings, stamped/deep drawn shapes, bearings with locating notches, lubricant holes and grooves, customized designs

|

|

Precision Assembly Dimension & Size Composite Metal Bearings For Fluid Power Systems Pump Bushes Images |