| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Journal Bearing Type - Coiled Steel Backing

Model Number : TEX Bushing,Customized Bushing , Fiber Bush

Certification : DIN 1494, ISO 3547

Place of Origin : Valve Bushing Manufacturer

MOQ : 500 Piece/Pieces (Min. Order)

Price : negotiable

Payment Terms : T/T

Supply Ability : Valve Split Steel Bushings Shaft Bearings Suppliers

Delivery Time : 7-25 work days

Packaging Details : PLASTIC BAG+ CARTON+PALLET

Bushing Size : Customized Drawings

Bearing Material : Sleeve,Steel,SS316 Steel Copper Material

Material : /

Product name : Valve Bushing

Bearing Bushing Factory Price : tiffany@viiplus.com

Self-lubricating Bearing Bushing Manufacturer : https://www.viiplus.com/

High Light : Valve bushings suppliers

self-lubricating, metal-polymer plain bearing : Metal-Polymer Anti-Friction Plain Bearings

Bush Bearings Manufacturers Suppliers Exporters : plain bearings. Long, maintenance-free service, manufactures bushings in various designs and from different materials. tiffany@viiplus.com, Bushings - Configure and purchase - https://www.viiplus.com/

The Kevlar woven bearing valve bushing, constructed from stainless steel 316, offers a robust and high-performance solution for various industrial applications. The combination of (Polytetrafluoroethylene) and Kevlar woven material creates a unique material with excellent chemical resistance, low friction, and high temperature tolerance.

The stainless steel 316 backing material provides superior corrosion resistance and durability, ensuring the bushing can withstand harsh environments and demanding operating conditions. The Kevlar woven reinforcement adds strength and rigidity to the layer, enhancing its mechanical properties and wear resistance.

This bearing valve bushing is designed to provide smooth and reliable operation in valves, pumps, and other fluid handling equipment. Its ability to handle high pressure, corrosive media, and extreme temperatures makes it an ideal choice for critical applications in industries such as petrochemical, chemical processing, and marine.

By combining the strengths of , Kevlar, and stainless steel 316, this valve bushing offers a long-lasting and dependable solution for maintaining the integrity and performance of fluid systems.

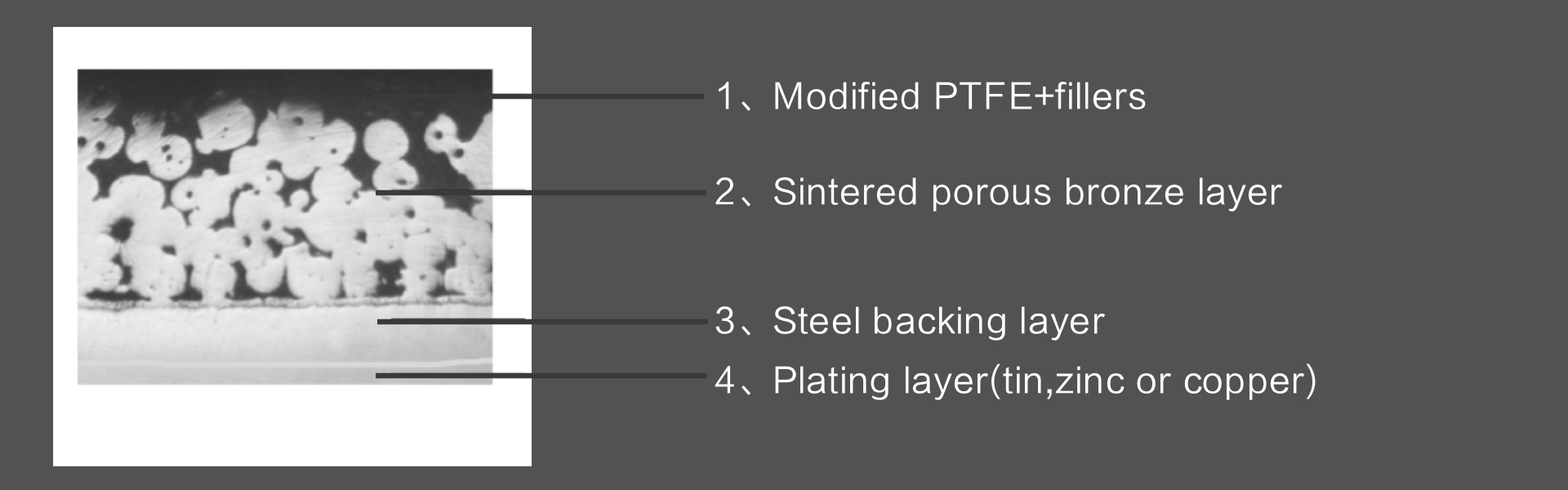

Kevlar reinforced high-performance material The valve bearing is a composite material of compounded tape on a metal shell. This material structure enables machining of the bearing in the housing--which is an alternative to the sizing process--to obtain tightest tolerances on the inside diameter.

The very thick layer isolates noise and allows to design bearings without play. Bearings of more than 0.75 mm thickness can be produced with an interference fit in the housing. Various methods are available to protect the steel shell from corrosion.

Bushings Metric (mm)Imperial (inch) Dimensions Get A quote.

Tolerances, operating clearance (Bushing data)

Shaft and housing tolerances (Design of bushing arrangements)

| Wrapped composite sliding bearing, tin-plated steel/, DIN 1494/ISO 3547, Maintenance-free | |||

| TECHNICAL DETAILS | |||

| Specific load capacity static | ≤ 250 [N/mm2] | Temperature strain | -200 [°C] to +280 [°C] |

| Specific load capacity dynamic | ≤ 140 [N/mm2] at low sliding speed | ||

| Sliding speed | ≤ 2.5 [m/s] | Max. PV-value | 1.8 [N/mm² x m/s] 3.6 [N/mm² x m/s] for short time |

| Friction value | 0.03 [µ] to 0.25 [µ] | ||

| MATERIALS | |||

| Support material | Steel tin-plated | Intermediate layer | Sintered bronze |

| Sliding layer | |||

| TOLERANCE DETAILS | |||

| Housing Ø | H7 | Shaft tolerance | f7 or h8 |

| Bushing inner-Ø after mounting | H9 | ||

| SHAFT MATERIAL | |||

| Steel, hardened or untempered. | |||

| Surface roughness ≤ Ra 0.8 | |||

| PROPERTIES | |||

| It is a maintenance-free material due to the sliding layer. Outstanding sliding and wear performance. High load capacity and very versatile bushing. | |||

| RANGE OF APPLICATION | |||

| hydraulic cylinders, cranes and construction machinery, all sorts of production machinery, pumps and medial devices | |||

| MAINTENANCE | |||

| It is maintenance-free with a sliding layer. It is not necessary to lubricate this material, but basically possible! | |||

| MOUNTING ADVISE | |||

| Housing | Mounting bevel min. 1.5 mm x 15-45° | ||

| Shaft | Mounting bevel 5 mm x 15°, edges rounded | ||

| The application of an adequate force fitting mandrel is advisable. Grease lubrication of the outer surface may be necessary when mounting. | |||

| Gluing | Adhesive should not contact the sliding surface! | ||

| Physical and Mechanical Performance | |

| Load capacity P(Dry friction) | Static load 250N/mm2 ; Dynamic load 140N/mm2;Oscillation Load 60N/mm² |

| Max line speed V | Dry Lubrication 2.5m/s;Oil Lubrication >5m/s |

| PV value limit | Grease Lubrication 1.8N/mm²· m/s;Oil Lubrication 3.6N/mm²· m/s |

| Friction coef u | Dry Lubrication 0.08~0.20;Oil Lubrication 0.02~0.12 |

| Mating Axis | Hardness >220 HB;Roughness Ra=0.4~1.25 |

| Working Temperature | -200~+280℃ |

| Thermal conductivity | 40W/(m·k) |

| Coefficient of linear expansion | 11×10-6/K |

| Production Process | Material cutting~Bronze sintering~ sintering~Sizing~Coiling~Surface finish~Packing |

| Application Feature | Self lubrication, Low wear, Low friction, Low noise, Good sliding characteristic, Pb free |

AUTOMOTIVE

With the advantages of low weight, low noise level and self-lubricating properties,VIIPLUS bearings are widely used in the automotive industry and applications are still developing rapidly. Currently, over 50 bushings are used in every passenger car, and more and more traditional needle bearings are being replaced by sintered bearings with self-lubricating bearings. In addition to the bearing,

· Steering & Suspension System

· Power Transmission System

· Body System

· Other

INDUSTRY

While the high efficiency and high precision requirements of modern industry are the basic requirements, environmental protection and safety are increasingly being considered genetically. The performance of CSB bearings have the advantage of minimizing maintenance frequency and oil consumption, as well as improving working conditions by reducing the operating noise level of the machine. Even in conditions of lack of oil ...

· Stamping Machine

· Injection Machine

· Presser

· Robot

In addition, household appliances such as air conditioning, fitness equipment, washing machines, refrigerators are also widely used.

FOLLOW US ON

HTTP://WWW.BRONZEGLEITLAGER.COM

|

|

Kevlar Woven Bearing Valve Bushing Made Of Stainless Steel 316 Images |